Think People.

Think Haynes.

When you need people Haynes delivers. We specialise in volume hires within the Renewables, Civil Construction, Manufacturing, Warehousing, Transport & Logistics, Hard Rock Mining and Agriculture.

Haynes offers clients tailored insights into market trends and regulations for our specialised industries. We are well-equipped to find the right skilled workers to join your site or head office, from trade assistants and site supervisors to engineers and planners.

Our labour hire and recruitment expertise

- Renewables

- Civil Construction

- Manufacturing

- Warehousing, Transport & Logistics

- Hard Rock Mining and Agriculture

Our Commitments

Safety is non-negotiable

People do amazing things, and we believe they have the courage to shape a smart, safe workplace. We enable this by creating a supportive, innovative, fun culture. One that is honest, open, and based on mutual respect.

We know our market

We know that laws, regulations and economic conditions are ever-changing, and it isn’t easy to keep up to date. Our team values connectedness and knowledge sharing, so everyone stays in the know. we’re committed to delivering useful information to our clients to ensure they stay up to date with the latest developments in their industry.

Customer-first

In the fast-paced recruitment and labour-hire market, responding to and meeting customer requirements in a professional, accurate and timely manner is critical. With established relationships and market contacts, our response time for providing the right recruitment solutions for our customers is what differentiates Haynes in the market.

'One Stop' recruitment provider

Pre-qualified, work-ready candidates

A pre-qualified, work-ready candidate is a person who has been carefully screened and evaluated to ensure they possess the necessary skills, qualifications, and experience to successfully fulfil a job role.

Request Staff

Get in touch with our team to find out how we can help fill your vacancies.

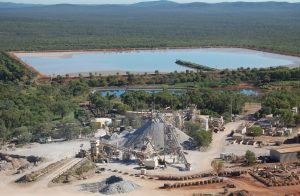

Projects we’ve worked on

At Haynes, we offer our clients responsive, reliable, end-to-end labour hire and recruitment, enabling continuous productivity every day.

With staff in offices across Australia, we have a strong understanding of markets and our recruitment specialists are always ready to offer expert insights into updates and trends within your industry.

Since our beginning in Western Australia in 1990, we have grown to secure our position as an Australian leader in labour-hire and recruitment with a network of officers across the country.

Trusted for over 20 years

Looking for staff?

Streamline the onboarding process and get new candidates quickly screened, inducted, and mobilised for maximum productivity.

Looking for work?

Thousands of individuals in Australia have taken advantage of fresh employment opportunities provided by Haynes. Search our job postings to uncover your next role!